| Inner size (W*D*H)(cm) |

80*70*90 |

100*100*100 |

120*120*120 |

315*516*195 |

Customize |

- |

| Outer size (W*D*H)(cm) |

70*125*157 |

70*135*167 |

90*157*185 |

90*188*195 |

120*185*215 |

120*295*215 |

| Net weight (kg) |

Based on the situation |

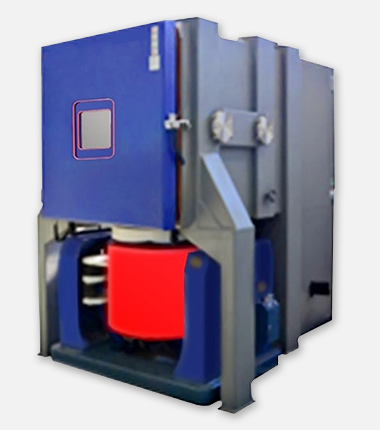

| Exterior material |

Standard 1.2mm electrolytic plate electrostatic spray paint |

| Interior material |

Stainless steel plate SUS#304 |

| Temp Range |

-70℃ to 150℃ |

| Humid Range |

20%RH to 98%RH |

| Cooling Rate |

Standard 1℃/min;

or specified |

| Heating Rate |

Standard 3℃/min;

or specified |

| Frequency Range |

3-5,000 Hz (Adjustable) |

| Sine Force (kg) |

300kg to 35,000kg for choose;

or specified |

| Displacement (mm) |

Please see vibration shaker details |

| Max load (kg) |

Please see vibration shaker details |

| Floor Load Resistance |

Customized |

| Configuration Interface |

Configuration interface |

| Power supply |

AC 380V 50Hz |